-

Posts

758 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by mr 580

-

Topic description “Volvo D4 service tech near Wilson, NY” is where I got model reference. I looked it up as I was curious as to who was servicing Volvo marine diesels and I did see the Canadian dealer listed.

-

Original post references Volvo D4 which shows to be a common rail design likely mid to late 2000’s vintage. This would be an electronically controlled system. If memory serves me right, we started seeing electronic controls in the mid to late 90’s. Most of the mechanical systems were gone by 2010. Emissions drove much of the changes. The electronics are generally trouble free, but when you do have an issue proper diagnostics are critical. Not a good idea to just start swapping parts. I think Mr. Powell is making a good choice in checking service options before purchase. Another person to contact that might have some insight on Volvo diesel service would be Fran Brobeil at Brobeil Marine. I know he is Volvo dealer for gas engines and might know where one could get help with diesels.

-

Agree that basic designs are similar. Where the OEM’s make it more difficult is in the diagnostics and there is no standard in cabling and software. When I retired about 5 years ago some of our road techs were carrying 2 laptops in their trucks for various vendors. I was the guy who bought this stuff and negotiated with the vendors for multiple locations so I know how it works. If I were looking for Volvo service in WNY, I would talk to Vantage in Batavia or a Volvo truck dealer to see what their thoughts were on marine engine service.

-

I worked for a heavy equipment distributor for many years and disagree with the thought that “certification” of techs and dealers is merely a piece of paper. The manufacturers have some pretty rigid standards of both training for techs and purchases of required service tooling. Each tech would get several weeks training per year and hardware/software would run several thousand per location. Beyond basic engine oil or fuel filter changes, there is not much that can be done on modern diesels without having electronic diagnostics most of which are proprietary to the manufacturer. I have seen $10,000 ECM’s fried by a misplaced electrical probe. It’s fine to have a local guy do routine PM’s, but when you have a problem it is a good idea to know where trained people are. Travel time and mileage for these techs are big dollars.

-

Variety of factors in the design of the boards effect position of the tow point. In general terms the vertical placement should be as high as possible as you want tow line as high off water as possible. Once tow line hits water that is effective distance from boat. The horizontal location needs to be back so boards bite and pull out. Many double board designs place the outside board forward of the inside board to help bite. Performance on most double board setups can also be enhanced by using weight on the outside board. I use homemade boards and pull with an eyebolt on top of inside board. The process of locating tow points with something homemade is a trial and error process. Over the years I’ve made several sets before settling with a design that I’m satisfied with.

-

Several good choices - I’ve been running AFW Camo 7 strand. The Camo is a brown finish-think it might be a bit more stealthy than a bright finish. Key to using any wire is keeping tension on it at all times and watching for pig tails.

-

Believe it runs $5,000 for unlicensed another $5,000 for drug testing even on UPV . Additional if running a mate or more than 6 passengers. Can add up to some pretty big numbers as some of these are per occurrence. Would be an expensive lesson to get pinched.

-

Have the diver slide on braid or mono whichever you prefer. For guys who do the “Babe Ruth” hookset, you might want to run a clear snubber before your leader. Gets expensive when your rig gets busted off.

-

On my wire roller rods I use an improved Albright knot to connect wire to 80lb braid for the slide diver. Do a “search” on the topic and you should find plenty of info. With the 30lb wire I think braid is a better option to connect than mono. If you wanted flea protection you could just use a short section of braid for wire connection then do a double uniknot to connect braid to mono for diver to slide on. Bit of a learning curve in using/setting slide divers but once you get it down they work good.

-

Years ago I had a set of plastic folding boards with Cabelas brand. Thought by folding they would store neatly. What I found was they didn’t run very good and storage was still an issue due to length. IMO hard to beat in line boards when storage is an issue.

-

I don’t know of a standard date code. With mono I write year of purchase on spool. I also try to buy line where it is sold in quantity so hopefully inventory is “fresh”. Store in tote in cool dry place. If in doubt throw old mono out (or recycle).

-

Lots of possible causes of a mid range misfire in an outboard. Might want to proceed carefully in repair to a 1998 Evinrude FICHT as Evinrude had issues in that time frame which lead to bankruptcy in 2000. If some fuel filters or spark plugs won’t fix the miss, it probably isn’t worth putting much into repairs on this age outboard. Probably should talk with an old Evinrude dealer or marine repair business. BRP did a redesign on the Evinrude after they assumed ownership so the later engines are different from the old OMC product.

-

Pretty happy with a Ruger American in 7mm 08. Killed a couple deer with it this year. With short action nice light gun to carry. Price was good on gun, but it needed tweaking to get it to shoot decent. Had to sand down stock for barrel clearance and properly torque mounting screws. Like the cartridge- as far as the Ruger American- cheap gun/cheap price. It kills deer, but if I had to it over I would spend more and gotten a higher quality rifle with better fit/finish.

-

IMO several conversations going on in this discussion. First, weighted steel compares to lead core and copper as a means to achieve depth with each having plus/minus issues. Second, likely some additional depth could be achieved from each of the weighted lines by attaching them to 19 or 7 strand wire. This combination likely would function fine as a chute rod as the wire has constant tension with few bends. The last conversation is one of attaching 19 strand or 7 strand to a board with a release mechanism. To me this is where the lights start flashing. Twisting wire, having tension differences all lead to wire line failure. If the wire fails you likely lose board and everything attached. Wire is just not a good choice in a release. Braid or mono all function well as board attachments. To me fishing with weighted lines using high speed reels, using shorter sections along with snap weights/ torpedo weights help maintain the fun factor. For less experienced guys keeping it simple helps and saves some bucks.

-

-

-

-

With the high speed cannons like the Mag 5ST, it really helps to run a ball snubber to take out the snap when the auto stop breaks the surface. Amish Outfitters makes one that is reasonably priced and holds up well. If you are fraying cables you need to check how your cables are installed. I run two Mag 5ST’s and have zero issues with cables fraying. I do check and change my probe rigger termination annually. The Cannon terminators are very trouble free. Get your cable routing sorted out and a couple of ball snubbers should fix the break off problem.

-

The way I look at it the Simrad is a touchscreen unit-the only button on it is the power button. So all your info is via touch-way points can be entered several ways and to me it is a matter of getting used to unit. A few swipes and it is in-do it a few times and no big deal. I liked the fact it was compact and the screen was bright in sunlight. I also generally run more off my tracks vs going way point to way point. I've attached a picture of my dash with GO7 chart plotter and you can see how compact it is. My Lowrance Gen 2 touch is to the left and that takes up more space with it's row of buttons. Like anything every unit has plus and minus- you have to judge what is best for you. Operation in bright sunlight was important to me and I had a buddy in Florida that put Simrads on his new center console and he really liked them in the Gulf.

-

-

10lb are fine and fishing shallow could go to 8lb. Some folks feel using a smaller ball creates less disturbance and is more “stealthy”. Based on number of eyes in Erie now, I don’t know that I would run out to buy a bunch of different rigger weights. I run a 10lb and a 13lb on probe rigger-I tend to fish up off bottom especially with probe rigger. Over the years I’ve found this to be more “economical”. For eyes a spoon fluttered off a rigger puts fish in the boat especially when it is a bit slow.

-

-

Rated up to 20lbs

-

My depth raider has been reliable and trouble free. Like others have said pros and cons with both depth raider ad fish hawk. If I was buying a unit today, I would probably go with the fish hawk as I think they have a bigger market share and a good reputation for customer service. Depth raider decent price/product from a small company. The smart troll I kind of view as a item that is used as a complement to a speed and temp system rather than a direct competitor. For someone wanting additional info good tool, but for basic info a rigger mount speed temp unit is the way to go.

-

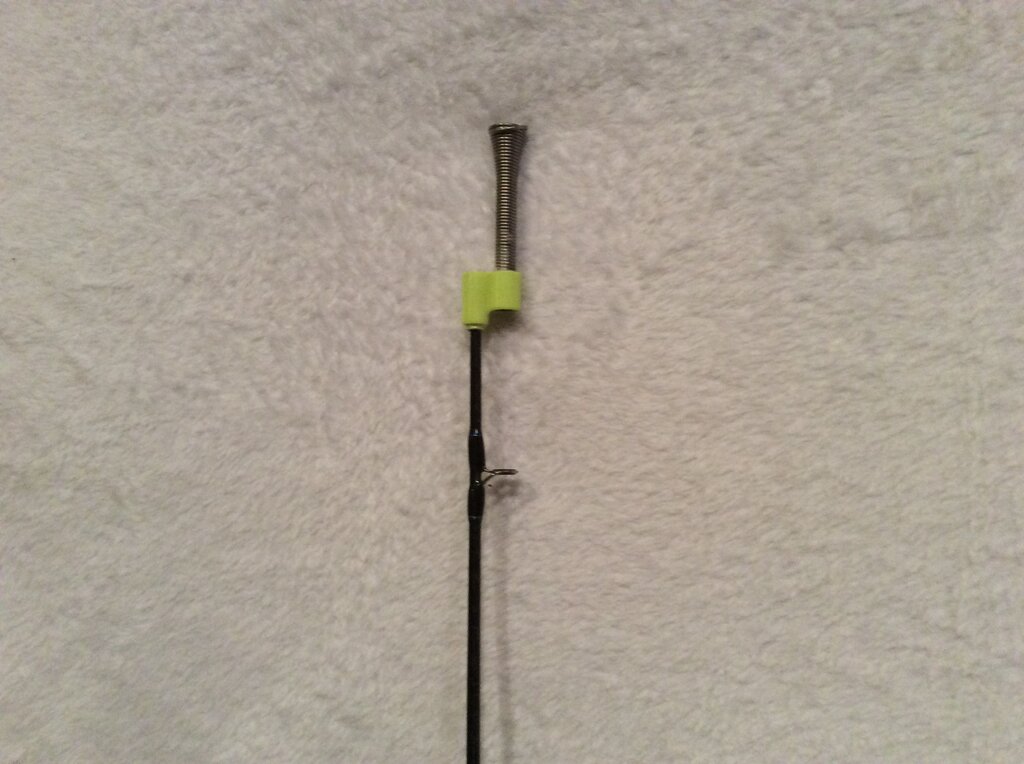

I'll share a couple pictures of my slide diver setups. If you're fishing Lake Ontario exclusively the regular slide diver (no light bite arm)works fine- I run surgical tubing under the lock arm and add a couple of beads at back to protect the swivel knot. I always run a leader back to the lure and I vary length depending on spoon or flasher fly. For light bites I add a short piece of the small clear tubing that comes with the diver to use with braid. This slides over the light bite arm so your line doesn't fall out of the arm. This tip is a time saver for setting lights as you don't have to watch or put line back in arm. I also add a couple beads to protect that knot as well. With wire I add a small section of braid to attach the mono to slide on. I put a drop of glue on the wire to braid knot to lock it. For mono I'm using Maxima 40lb leader material which seems to hold up longer than the 30lb I used to use. Mono leader is pretty reasonable in price for a coil of it. These setups have worked well for me. Never had breakoff issues and only maintenance is changing the slide mono when it gets difficult to let out.