-

Posts

766 -

Joined

-

Last visited

Everything posted by mr 580

-

Salmonite, the pug you have pictured in your original post would typically be used as a battery charger plug so you could easily access it on bulkhead or some easy to get to spot with a 110v extension cord. It is not a shore power plug as those ends are completely different. Guys have used household 110 plugs, boxes and wiring for 12v riggers- it can work but not best practice as marine wiring is a better choice. If you find wire nuts plan on doing the wiring over with the right materials.

-

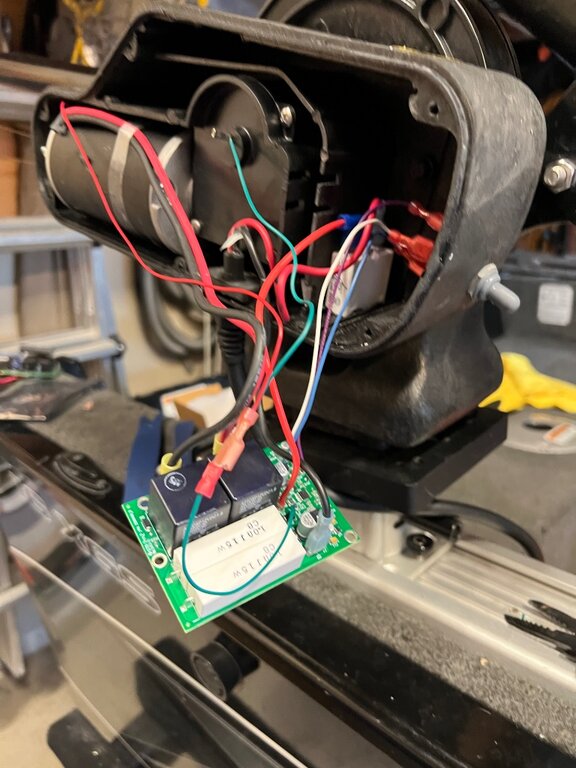

You don’t necessarily need to replace that rigger right now if it functions with the switch. You can remove the keypad and caulk up the holes and continue to use it less the keypad. Those old and slow Mag 10A can continue to work especially if you stay with weights less than 10lb. Not many parts available and motors are especially hard to find. If it works use it-just don’t put much money into it. In the meantime you can be on the look out for something newer that can handle heavier weights.

-

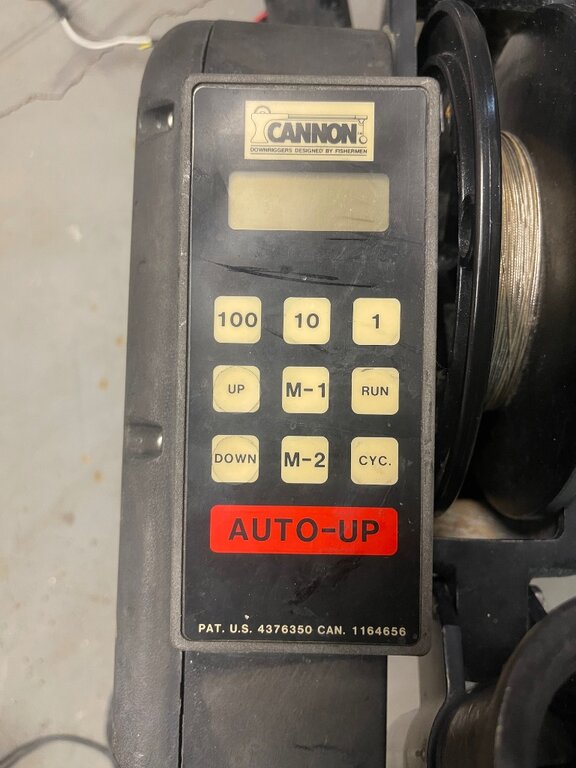

That is an original Digitrol- not sure when those were made but I know the Digitrol 2 was out in the mid to late 80’s as I had a pair. I don’t think you’ll have much luck finding a display as they haven’t bee available for at least twenty years. Guys kept them going by converting to standard Mag 10 and getting rid of display. Sounds like yours is setup that way with switch for up and down as Digitrol just used keypad.

-

-

Have had Cannon electric riggers since 1985 in various models including high speed models. For termination I’ve used Cannon terminators or Klinchers. On high speed models I’ve used Amish Outfitter Ball Snubbers. Zero issue with ball or probe loss. Replaced a couple circuit boards due to water intrusion and have corrected that. I understand being upset by loss of ball and/or probe and if I was in that situation I’d be looking to get a different result.

-

The marina under the parkway bridge on the east side is an Orleans County Park not a NYS Park.

-

I tried segmenting to put out different lengths- didn’t like the way the copper dragged in the water on the section between the boat and the board. All the different knots was a pain too. Quickly scrapped that idea. Just go with a length and let it all out.

-

Can i troll with my 4.3 Merc with drift socks

mr 580 replied to hookedagain55's topic in This Old Boat

Shouldn’t be a problem using trolling bags with your I/o- note there is a difference in a trolling bag vs a drift sock. Trolling bags are heavier. You should also be able to troll with kicker going straight and steering with your main motor-the turning radius and steering range likely not as good but it will work. Getting your kicker mount secure probably your best bet to get the most from your setup. -

Rod holders and rigger mount location - Sylvan Offshore

mr 580 replied to The force's topic in This Old Boat

IMO after rigging several aluminum boats for trolling is that installing track and backer really helps spread the load of added rod holders/riggers on the gunnel. Never done a Sylvan but my guess is some extra stiffness would be a benefit. The aluminum gunnel can be fairly light and show some flex on aluminum boats especially when compared to gunnels on glass boats. Use of backer material and added gunnel support is a consideration when doing your rigging. -

Rod holders and rigger mount location - Sylvan Offshore

mr 580 replied to The force's topic in This Old Boat

-

Rod holders and rigger mount location - Sylvan Offshore

mr 580 replied to The force's topic in This Old Boat

Push your riggers back further then go with a track system. Traxstech, Cisco, and Bert’s are options to consider. Get the longest track you can fit on each side. Then you can add rod holders and trees to fit your needs. If the kids want to tube you pull off the holders. Use a backer under the gunnel. There is expense up front but there is a lot you can do with a track system. -

-

-

Try Jann’s Netcraft- they have a good selection of rod building gear including guides. I usually do that work in winter so not sure what current availability is.

-

Wanted Pro Line windshield needed

mr 580 replied to Hot Soup's topic in Classifieds - Buy, Sell, Trade or Rent

-

I’ve found email to work for me in contacting them. Bought a noise suppressor for my kicker last September and some Lund 45 degree track mounts this spring. In both situations exchanged emails without any issues.

-

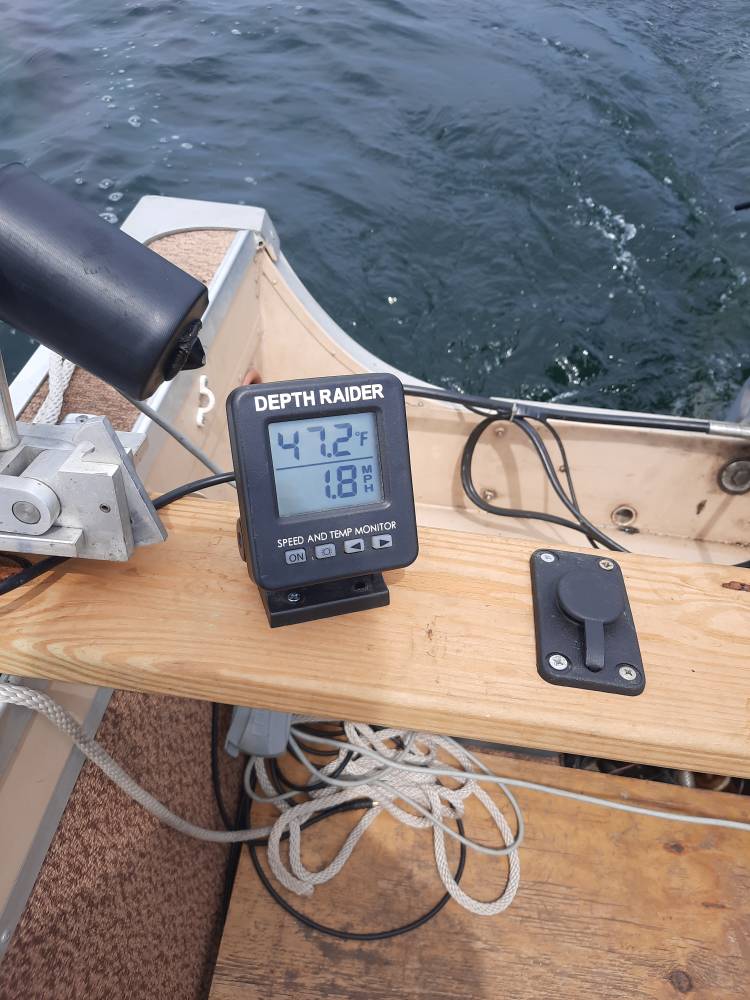

Earl is correct that you need 12 volt power to the display. You should also have coaxial cable from display to antenna that mounts on rigger, coated downrigger cable for signal and probe with 9 volt battery. Google Depth Raider and you should find info on install and termination for probe connection.

-

-

Replaced one servo on my old Trollmaster 2 in 10 years. Was only issue I had with that one other than some waterproofing I did. Updated to Suzuki efi kicker year or two ago and have been happy with that Trollmaster 2 - some other choices out there that are probably good but I didn’t see a reason to change.

-

In 12 to 16 FOW a couple colors of leadcore or small snap weight on a board are a couple better choices than trying to run a diver that shallow. Divers including SD’s are effective tools - that being said fishing them close to the bottom can be costly.

-

The issue I had with Trollmaster 3 was that it was remote only with no backup if remote or it’s battery quit. I went with the hard wired Trollmaster 2 as I had good luck with that on my previous kicker. I guess I’d price the parts that you need to get the Trollmaster 3 working and decide if it was worth investing the $$$ or starting over.

-

If you have Sealine Great Lakes Special 47LC’s, it could be bushing wear on the spool. When the bushings wear the spool will bind. Later versions have bearings. Could also be the wire binding coming off the spool- real important to spool the wire under a lot of tension to prevent it from digging in the spool.

-

Big board planer rod angles, etc

mr 580 replied to HoundsNTrout's topic in Questions About Trout & Salmon Trolling?

With big boards it is important to get the angle of your tow line as great as possible. Once your release or tow line contacts the water then that is effective width you can achieve with that board. So having your mast or tow point as high as possible creates your maximum distance. Same goes with your front rod going out the furthest by keeping it high creates the greatest angle. IMO a 19’ with 6 foot mast probably best with 2 lines per side based on tow line angle. For that application likely in lines would provide a greater spread. In lines make a lot of sense especially in smaller boat packages. -

A picture of what you have going on would help. If you do have a Digitrol 2 and the top mounted control pad has been disconnected usually that is because the pad has failed. The control pads for the Digitrol 2’s haven’t been available for years. Used to be able to do a work around by converting to Mag 10 switches and no control pad. Probably would need to find used parts as not much available for that vintage of riggers.

-