-

Posts

13,872 -

Joined

-

Last visited

Everything posted by Sk8man

-

I do use the offshores and others as well. Commonly use 4 oz but depends on what I'm running and the water conditions and water depth.

-

Most likely it is your own computer or device that is at fault.

-

Most of the time I add it right at the connection of the fluoro leader but I sometimes run it at the connection of the backing and copper depending on what I'm running. If I am running heavier stuff at the end I use the former and for sticks etc. I use the latter most often. After awhile you can tell by the feel of the rod and tip which point seems better for that particular setup.

-

Try using a flyrod with small black wooly flies or streamers (e.g. red ones)

-

Good plan

-

I camped at Sampson for years but never in the fairly new cabins. There are about 240 campsites and good bathroom facilities etc. At one time had a self-contained camper as well as tents. Tenting is not bad there and and no matter which site you choose (most are electric) water and facilities are in easy reach and the launch is within a couple minutes of any of them. Sampson and Cayuga Lake State Park are pretty busy campgrounds and often the sites fill up fast. Cayuga is also a real nice campground (just there past weekend) with many amenities and a wide range of sites, and swimming beach etc. and cottages but they are probably filled up for the season early)The launch there at the park is quite low water so I launch up the road about 10 miles south on Rt#89 at Dean's Cove where you have nearly immediate access to good fishing. There is a fee and a kiosk there in the parking lot that only takes credit cards no cash.

-

I think the key here is "long" coppers. It is the length of time bringing in the fish say on a 600 copper that is critical. I don't use anything longer than 300 and add weight if needed. 100 yds (length of a football field) is a long way behind the boat just for the wire alone.

-

He has helped out a bunch of buddies and in each case total satisfaction with the job done....rare level of competence in these times and highly commendable

-

John said it right Nick. Both you guys give helpful reports and information and it is based on solid knowledge and experience. It is unfortunate that anyone would make negative comments but it is the world we now live in where folks no longer trust each other, question their intentions or motives, or get off on antagonizing people by their negative comments. Don't let it discourage you from doing it. Keep at it out there. I for one hope that Seneca recycles or re-boots itself to the levels of times past. Folks should not forget that Seneca is not a stagnant body of water; it is very much alive and ever changing all of the time and "cleansing" itself via the Seneca River and the strong lake currents etc. Some other bodies of water may not be so lucky. Still my favorite Finger Lake with lots of room for everybody

-

Back to Jigging

Sk8man replied to Pete Collin's topic in New York Fishing Reports - Lake Ontario (South Shore)

-

-

You are right about the knot stuff but despite some folks aversion to wire crimps I have used them for 40 plus years and never have problems with them if carefully applied and routinely checked as should be done with any line or connection points. You do need to use the right size for the particular wire diameter used though.

-

You may wish to consider the 19 strand wire (if you can find some.....most placed are backordered). Some folks have suggested that it keeps the fleas off better and is less liable to kink. They all work if you are careful in deploying and maintaining them by keeping tensions at all times.

-

Bob- The tool seems to work best scraping across the wire which offers some resistance to it. On mono it didn't seem to work as well because the mono doesn't give the resistance to it but I used it to scrape them down the line and into a clump which i removed most of by hand. On the copper I kept the braid backing to a minimum out and didn't have any significant fleas (which seemed like a real blessing) They weren't to the extent that they collected on the .downriggers so that wasn't any problem at least at this time out. The flea tool seems to clean off relatively easily by dipping it in the water and moving it back and forth. I keep 4 of them handy

-

Sink rate for Monel

Sk8man replied to hookedupf7's topic in Questions About Trout & Salmon Trolling?

Used to be used on A and S reels some victrolas and other bottom fishing and hand rigs similar to pulling copper but it is very soft and very easily kinks. The sink rate was pretty similar to some single strand copper (not the braided copper we now use on copper rigs) which varied in diameter usually 018-.030 in. I think the sink rate may have been most similar to the .024 in. diameter. It is a soft dull colored silver wire ( when used - similar to the look of solder). -

Henderson Harbor

Sk8man replied to markdaniel's topic in New York Fishing Reports - Lake Ontario (South Shore)

-

-

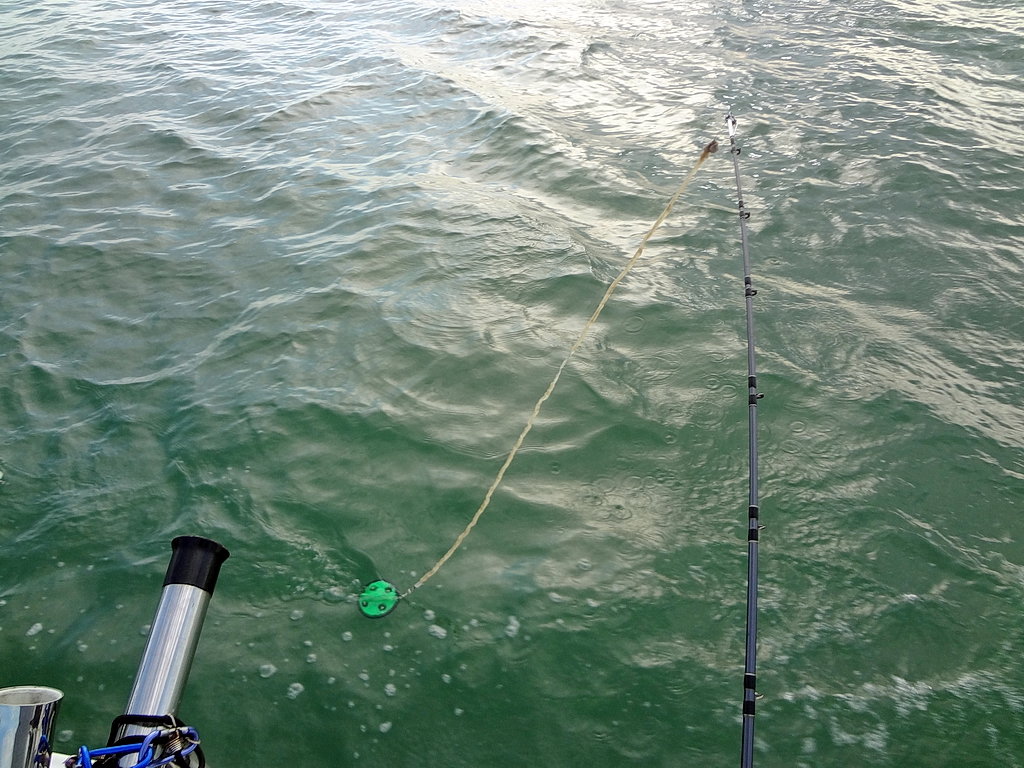

Fun derby. My son and I camped the weekend at Cayuga Lake State Park and launched at Dean's Cove. We caught a bunch of fish mostly lakers one ten pounds and another about that and many 5-8 lbs biggest salmon about 7. It would sure be nice if they had a weigh station somewhere closer to the fishing (e.g. Long Point maybe?). heat was brutal fleas were pretty bad too. The new tool (paint stick with velcro) worked but it isn't a total panacea or solution especially for mono lines. Never had any fleas on the 300 copper though. Pics of a couple of the fish:

-

X2

-

You have to really watch the heat application (transfering through the metal tip to the rod itself) to the fiberglass it can weaken it if too much. The new packages of twillis come with a few different inside diameter adapters that fit most standard rods but if you now have a rod tip diameter that is too large for the largest inside diameter you may have to go with a roller tip instead. I like them better anyway. If you go the roller approach look around for a used roller tip rod that has the steel tips NOT the ones with aluminum sides they allow wire to cut through them

-

Nice going Wes. Thanks for the report. Maybe see ya out there this weekend we'll be launching out of Dean's. I'll bet those folks are still talking about the fishing Good luck in the derby if I don't get a chance to connect.

-

Kicker took a swim

Sk8man replied to Killerk's topic in New York Fishing Reports - Lake Ontario (South Shore)

-

Kicker took a swim

Sk8man replied to Killerk's topic in New York Fishing Reports - Lake Ontario (South Shore)

Ive had my Garelick bracket since 2002 and this is the second motor on it.....never a problem and I've trailered with it vertical the entire time. My bracket is bolted through the hull and backed on the underside and outside. The motor doesn't move when trailering. I have it secured with a lock so that the hand fasteners can't loosen up and I have a ratcheted strap around the metal part of the bracket to keep the motor tight and to act as a safety line in case the plastic fails. Is it a garanteed perfect failsafe measure? No but I've tried to eliminate the major concerns at least. It is unfortunate situations like this that causes you to question your own set-up as well. Good luck from here on out Killerk hope things go better for you. -