-

Posts

784 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by John E Powell

-

Sold / Closed lee outrigger bases and 18 foot poles. quad big john rod holders.

John E Powell replied to machzrcr's topic in Classifieds - Buy, Sell, Trade or Rent

-

Wanted Rod makers?

John E Powell replied to ERABBIT's topic in Classifieds - Buy, Sell, Trade or Rent

Are you looking to have the few problem guides replaced or new rods built to suit your needs? I can generally replace guides between builds, but I've got a bit of a backlog on rod builds as this is the busy season for custom work for me. -

Mike is doing some work for me also.

-

Power pro braid is popular, I have heard the 80lb class holds in the slide diver better than the smaller, but that's 2nd hand info.

-

You can run slide divers off mono, braid, or wire. Mono goes widest spread and shallowest, wire has narrowest spread and goes deepest, and braid is in between the two. Mono is more difficult to trip with long distances, but it's stretchiness helps to keep from pulling hooks from soft mouth trout. It can be challenging to clean summer fleas from braid, wire is comparatively easier. They all have their used, it depends on how you want to use them in your spread throughout the season.

-

Greater Niagara fishing and hunting expo

John E Powell replied to rolmops's topic in Open Lake Discussion

I do think it's unrealistic for people to complain that other people didn't bring their used gear to sell. There were many of the same vendors with the same cut price deals, they were just in the main show this year for all three days. Would you rather pay an entry fee and have bath fitter on the main floor? I think this is just the natural evolution of the show. Would it have been nice to have twice as many people occupying tables, sure. But people have to step up for that to happen. LOTSA can't compel people to sit at a table and sell their used gear. -

Greater Niagara fishing and hunting expo

John E Powell replied to rolmops's topic in Open Lake Discussion

As the show has grown in popularity, many of the vendors who previously payed for booth space for the one day marketplace have elected to purchase space on the main floor for three days. The marketplace was basically a venue for tackle shops to offer clearance items and pricing or for captains or private persons to sell their used gear. I know I pretty much sold out of my used gear the first year I attended. The second year, I paid for a booth to support the club, but I had so little left to sell I didn't break even. Last year, I donated a custom rod for the club to raffle off. My cost was far more than the table price and again no sales. This year, I decided I wanted to go to some of the classes so I didn't make a donation for a table. I'd like to personally suggest that each and every person who complained above about the marketplace do something to make next year's event better. You should put your money where your mouth is and go through your stuff, buy a table, and sit there all day to make the show better for everyone else. My commentary in no way represents the opinion of LOTSA, the directors and officers, or any member. My words here are my own opinion. -

I have experience with both systems. The Cisco are the stronger more durably built product and I'd recommend them for pulling the really hard-pulling boards like the Amish Outfitters, but the BJ will get the job done for many people with more modest needs. If price is a lesser concern for you, IMO the Cisco are worth the extra $.

-

Jerry was one of the good guys, rest in peace my friend.

-

Torpedo 19 strand, spend the few dollars more. It's easier on the guides and it gives you a warning if it gets damaged (it will form a small bird's nest where it's damaged); 7 strand wire can be difficult to see damage and you end up losing the dipsy, flasher, fly, and a couple ball bearing swivels. They both can fail, the 19 strand variety just gives you the better chance of saving the rest of your gear..

-

Wanted WANTED: Talora Rod Butt Cap

John E Powell replied to TyeeTanic's topic in Classifieds - Buy, Sell, Trade or Rent

If you can't find someone local, I've heard you can get replacements from Shimano. If you always run them, epoxy them in place. -

I have to wonder in what manner are you using / abusing them that you break 3-4 a season? Do you have a crew member who is high sticking them or dropping them against the inside of your gunwale (this can cause delayed failures)?

-

installing twill tip on shimano tdr?

John E Powell replied to slickrick's topic in Tackle and Techniques

You can certainly do that too ^^. Just realize, you void most mfg's warranty by shortening the blank. 😢 -

installing twill tip on shimano tdr?

John E Powell replied to slickrick's topic in Tackle and Techniques

I've changed and installed literally hundreds of tips. Some tips are fixed with a one part adhesive, others are epoxied. Both can be removed, adhesive tips are fairly easy but epoxied tips can vary and require care. The goal it to heat the metal very quickly to break the epoxy bond without cooking the resin that binds the fibers in the tip area of the rod blank. With epoxied tips its best to have three hands (someone holds the rod) or an additional clamp or vise to hold the rod. Small butane or propane torches work best, but a lighter or candle can also work. You'll also need some pliers and some cold water to cool the tip between attempts if it doesn't come off the first try. Grab the legs of the tip that support the ring with the pliers held in a manner that will allow you to twist the guide tube as it is heated. Apply intense heat to the tube for a split second while gently twisting the tube. If it comes free continue to twist as you pull it off the rod blank. If it does not come off, COOL THE TIP FIRST with water, dry it off, and try again. This is really important. You do not want to cook the resinous the rod blank from repeated or continual heating! Eventually the epoxy will fail from the rapid heating and cooling. Some things to look for: Sometimes the people assembling these get sloppy and wrap thread up onto the tip tube and then that gets epoxied on the outside too. If you have a rod like this it's best to cut back the epoxied thread to the end of the guide tube before attempting to heat the tube. The posters above make it seem easy, and it is if the tip is adhered with adhesive. It can be challenging to not damage the rod with epoxied tips. Over the years I've actually had to split the tube with a file on a few epoxied tips that refused to budge. To install a twili tip, follow the directions in the pack. To others who might read this, the correct product and method to adhere regular rod tips is this: http://www.flexcoat.com/learning-center/instructional-videos/installin-a-tip-top/ The product he's using in the video is Flex Coat Thermal Plastic Tip Top Adhesive. I use this for most of the repairs I do and also on most of my custom rods. Hope this helps... Oh yeah, as mentioned in a post above there's no benefit at all to heat adhesive, on purpose, until it ignites. The melting point of the adhesive is about 220 degrees. Flaming the adhesive risks damaging the blank in the short and/or long term. Sent from my iPad using Lake Ontario United mobile app -

I believe it's time to buy new downrigger rods What Brand?

John E Powell replied to Patriot's topic in Open Lake Discussion

Post a follow up when you've had a chance to fish with them. I know it might be a while, Mike texted me looking for blanks. Small world eh? Sent from my iPad using Lake Ontario United mobile app -

Canandaigua Crazy sailboat driver!

John E Powell replied to chuck527's topic in Finger Lakes Discussion

The "fishing vessel" is commonly misunderstood because it is not specifically defined in the regs. Recreational boats (which include 6 pack charter boats) are not fishing vessels. Think of commercial trawlers, draggers, net tenders, and processing vessels whose hulls or rigging would pose a hazard to commercial navigation or wildlife if either or both would run aground. Your planer board or downrigger would not be a hazard. -

It is not sufficient to rely only on battery orientation in a battery holder. You must confirm that the positive pole of one battery electrically connects to the negative pole of the other battery to form a series circuit. Without confirming this, it's possible the batteries are electrically connected in a parallel circuit (it's rare, but there are battery holders like this). Look for a thin metal clip (or possibly a wire) that acts as a jumper from one battery to the other. Don't be confused by wire(s) leading to and from the battery holder as these are not the jumper. Series circuit 3V and Parallel circuit 1.5V.

-

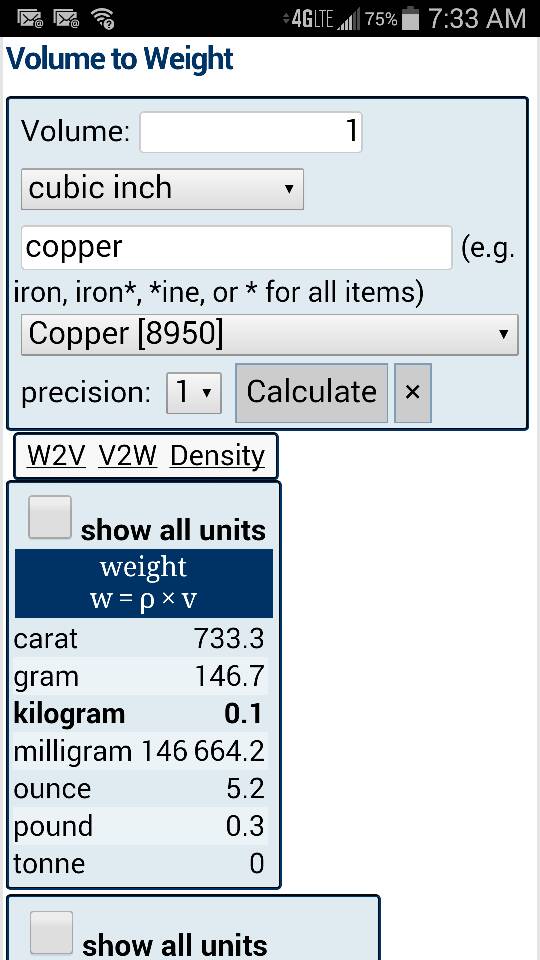

Paul, Volume wise (with respect to reel capacity), there's no real depth advantage to the 60lb copper over longer lengths of 45 or 32. What many people don't consider though is that at any given desired depth, you need less line out with heavier 60lb copper (compared to 45 or 32) which correlates directly to less cranks of the reel, which is the complaint most people express. A reel with a high speed retrieve (and less torque) pulling in a longer length of lighter copper can actually be more work than using a reel with a standard retrieve (and more torque) pulling in a shorter length of heavier copper. Based solely on studying the Blood Run depth charts and plugging the depth and diameter info into a spreadsheet to calculate the volumetric efficiency and retrieve per crank of some typical copper reels, one could make a case for getting the best of all worlds by using the 32 for shorter length up to 200-250ft and 60lb for all deeper depths. The more common 45 doesn't perform with the same volumetric efficiency as the lighter and heavier coppers.

-

Cannon Swivel Bases - Check for cracks

John E Powell replied to TileMan Dan's topic in This Old Boat

It's my understanding, and I could be wrong, that the bases and boom ends that have experienced problems were items sourced from a third party that cut corners. I have to wonder how many people badmouthing Cannon have contacted Cannon and been turned down on a replacement part? In my rather large circle of fishing friends I don't know of a single person who didn't get their problem resolved to their satisfaction. When I experienced a problem with one of my boom ends, Cannon sent me free replacements for all my registered riggers. -

I don't have a picture handy but I made one from some mahogany on my previous boat. if you have access to at least a jig saw (or band saw) and a large forstner bit (and a 1/2" drill or drill press) and a router with a roundover bit, it's pretty easy to do. The trick was to create a full size template out of cardboard to match the underside of your cabin top. Start out by hot melt glueing up some cardboard box sections in the approximate profile of the underside of your cabin roof. Then hot melt glue a strip of 1x3 along the bottom edge to support the cardboard to help keep it's shape. With someone helping to hold this up to your ceiling, rough trim the cardboard where it makes contact and/or hot glue smaller pieces where there are larger sized gaps. Once it's reasonably close, say within 1/2 inch all along the edge, use a compass with a marker installed to scribe (trace) the shape of your roof to the cardboard. Make sure to hold the point against your roof and keep the compass marker directly under the point as you trace the shape. Carefully cut the shape of your ceiling following the line and then check your work. Trim or add (hot glue more cardboard) where needed till it fits all along the roofline. Do this for both the front and rear where you want to store the rods. Trace the shapes on your material and cut it out. Check the fit and adjust any area that is more than 1/16" off. This will get epoxied to your roof once you get it fit and cut out all the rod supports with the forstner bit and jigsaw. Route the edges and sand. Get all this done and make any final adjustments before you fabricate the two side supports under each end. You create the sides with the same template technique. You can take a design cue from commercial made wood rod racks, but keep in mind your reel size, the commercial units space the rods too close to handle most large frame copper reels. If you have any carpeting or fabric liner, that will need to be trimmed so you can epoxy to the ceiling. If you or a friend is reasonably handy you should be able to construct a set over a weekend, finishing will, of course, add to the time to complete the job. Depending on how many rods you need to hang and how much room you have, it may be necessary to lay out alternating reel and tip ends. My recommendation is to try and avoid doing this unless you absolutely need that many rods hung. unless you have a very spacious cabin where you have room to turn your rods around, it will mean 1/2 your rods will have to be fed butt first into your cabin. This is a pain to do, it's far easier to feed rods tip first into your cabin.

-

Cannon Swivel Bases - Check for cracks

John E Powell replied to TileMan Dan's topic in This Old Boat

The swivel base pictured looks like an older style. If any of you purchase a new replacement base, the current revised style is Cannon part # 3991913. In my opinion, I wouldn't buy one of the older styles lots of places are selling online. You're likely to face a similar problem down the road. Here's a picture of the new upgraded base: http://www.fish307.com/cannon-low-profile-swivel-base/ -

For Sale : USA 01 30ft Luhrs open. Perfect charter boat

John E Powell replied to Bobtoy1's topic in Boats for Sale

-

For Sale : USA 01 30ft Luhrs open. Perfect charter boat

John E Powell replied to Bobtoy1's topic in Boats for Sale

-

A cleaning and service (including parts) probably would be half the cost or less of a new one. A local service I use: http://www.nyreelrepair.com/ Another well respected box and ship service: http://www.tunasreeltroubles.com/